Sustainability vs. economics

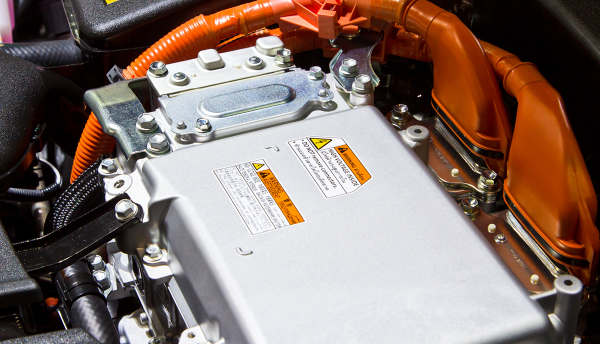

Battery-electric vehicles (BEVs) in operation will reach 171 million units globally in 2032, according to S&P Global Mobility. What will happen to all those end-of-life batteries? The race is on to recycled electric vehicle (EV) batteries. But at what cost and who stands to gain?

EV sales are blossoming but it is still a waiting game for battery recyclers. Where and when is the window of opportunity for high-voltage battery recycling? A new study by S&P Global Mobility on the battery recycling supply chain, policy and regulations and market sizing addresses these issues.

Policy support

While the EU passed regulations in July 2023 mandating EV battery recycling, the US does not (yet) have similar legislation in place, opting instead for recycling through incentives, as outlined in its Inflation Reduction Act. The absence of guidelines may hinder the repurposing of viable batteries before recycling, undermining sustainability efforts. Recycling requires less energy and generates less pollution compared with mining, but the sheer economics of recycling may not always be favorable without policy support.

Recycling car battery packs at the end of their useful life is not currently cost-effective or straightforward. However, those costs will tumble as the number of EVs on the road increases, enabling economies of scale. Some original equipment manufacturers, including Tesla, are ahead of the game by recycling up to 92% of battery materials to eliminate the need for mining new resources.

Recycling offers the potential to reuse a metal atom an infinite number of times, but the cost-efficient retrieval of materials is what matters to recyclers. The Democratic Republic of Congo is the main producer of cobalt, a costly component in lithium-ion batteries. However, manufacturers are working to remove cobalt from their battery chemistries and distance themselves from politically unstable countries in the process. This poses challenges to the recycling value proposition. Even without cobalt, batteries still contain valuable materials like lithium and nickel. Yet again, the economic feasibility of recycling materials, such as lithium, manganese and nickel, may be limited or require additional processing, which ramps up costs.

Closing the loop

Given the long lifespan of EV batteries, many batteries will have a second life as renewable energy storage long before being recycled. The future availability of batteries for recycling depends on various factors, particularly production scrap. Scrap generated during the manufacturing process of BEV batteries includes rejected or defective batteries and excess materials or components that do not meet quality standards. It consists of metals, electrolytes and other components. Scrap from cell production accounts for a large part of the total production scrap followed by battery pack production scrap and battery module production scrap.

Implications

Greater China currently holds the largest share of the global market for end-of-life new-energy vehicles (NEVs) due to its large fleet size and early adoption of NEVs. The study further predicts an increase in total production scrap in Greater China from 47.64 GWh in 2023 to 119.21 GWh in 2032, with end-of-life batteries expected to rise from 20.85 GWh in 2023 to 617.31 GWh in 2032. However, the total available waste batteries will likely increase from 68.49 GWh in 2023 to 732.92 GWh in 2032.

It is a different situation for raw materials. For lithium, we see a six-fold increase in demand between 2022 and 2030 from some 0.06 million metric tons to 0.37 million for light passenger vehicle applications alone. Consequently, lithium markets will likely be in deficit by 2027, creating a bottleneck for automotive supply. The resolution will be slow as lithium takes an average of 15.7 years to reach the market after discovery. Hence the recent focus on battery recycling.

We also expect some of the gap to mainland China to be clawed back as the market expands and the diversity of battery chemistries continues. Cobalt, for example, mined in the Democratic Republic of Congo (DRC) yet processed in mainland China, will be increasingly sourced and processed elsewhere toward the end of the decade to decrease reliance on the DRC and exposure to Environmental, Social and Governmental (ESG) risk.

A robust circular battery economy could reduce or eliminate the need for mineral extraction but that’s still a long way off.

S&P Global Mobility’s Component Forecast Analytics provides timely, reliable and comprehensive automotive component and technology data and powerful analytics from one of the most trusted sources in the industry. To learn more about our Battery forecasts, visit

https://autotechinsight.ihsmarkit.com/services/46971/battery