The shift from internal combustion engine (ICE) vehicles to electric and hybrid vehicles has driven the adoption of electric AC compressors. According to S&P Global Mobility's forecast, the demand for electric AC compressors was 22.5 million units in 2023 and is projected to reach 64.0 million units by 2030, with a compound annual growth rate (CAGR) of 16%.

Garrett Motion is a leading supplier of turbochargers and superchargers. To stay ahead in the rapidly evolving automotive industry and the transition to zero-emission vehicles (ZEVs), Garrett Motion is leveraging its core competencies to develop ZEV-focused products. The company has introduced three products specifically designed for ZEVs: the Fuel Cell Compressor, E-Powertrain and E-Cooling Compressor. Unlike traditional electric AC compressors, which are mostly the scroll-type, Garrett Motion's E-Cooling Compressor is the centrifugal-type.

To gain further insights into the E-Cooling Compressor and Garrett Motion’s initiatives in this area, we spoke with Frederic Gerard, Thermal Management general manager at Garrett Motion.

The following is an edited transcript of the conversation.

S&P Global Mobility: With the ongoing transition to electric vehicles, how has the significance of effective thermal management evolved?

Frederic Gerard: Effective thermal management has become increasingly significant with the transition to electric vehicles. It is key to addressing challenges such as extending the vehicle's range, ensuring quicker charging, and optimizing overall performance. Batteries, being the heart of an electric vehicle (EV), require an optimal temperature range for efficiency and longevity. Thermal management systems actively manage heat generated during various driving conditions, including charging, acceleration, and sustained high-speed driving.

Could you provide insights into the features of Garrett Motion's E-Cooling Compressor and explain how it differs from conventional cooling compressors?

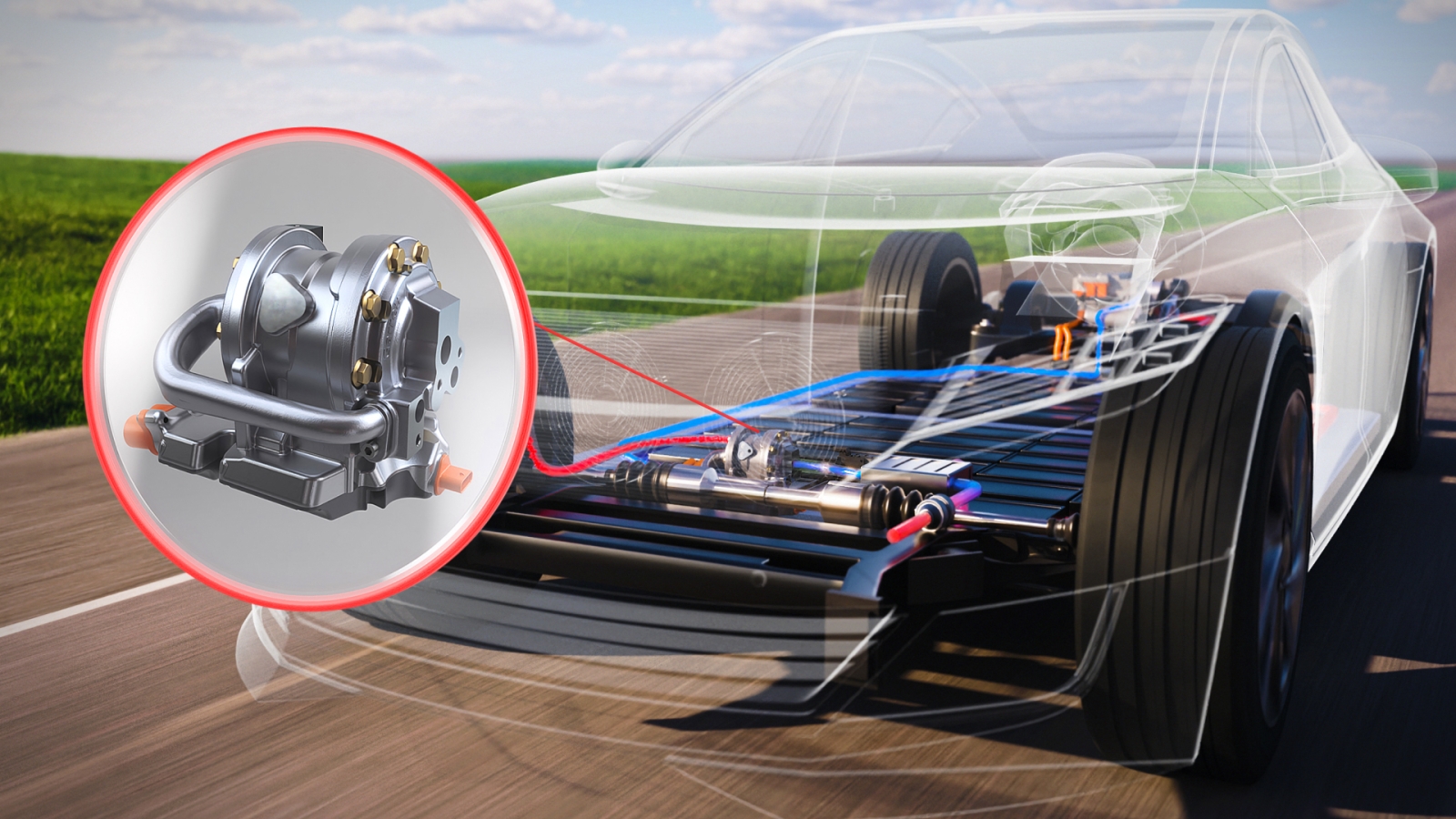

Garrett Motion's E-Cooling Compressor is a high power centrifugal refrigerant compressor designed for EV thermal management. It differs from conventional cooling compressors by operating at high speeds with a compact, lighter and oil-less architecture with much lower noise, vibration and harshness. This contributes to a more energy efficient thermal management system and enables ultra-fast charging, high-speed driving, improved cabin comfort, and simplified installation. The E-Cooling compressor enables up to 20% faster charging time and preserves the power of the motor whatever the battery temperature while also cooling the cabin up to 3 times faster than conventional compressors.

Image credit: Garrett Motion

Image credit: Garrett Motion

How does the E-Cooling compressor aid in maintaining optimal performance and efficiency of electric vehicles under cold weather conditions?

Maintaining the optimum temperature range is critical for the chemical reactions to continue inside the battery pack, ensuring the battery’s performance and longevity. Centrifugal refrigerant compressors effectively reduce the time required to bring the battery up to the optimum temperature compared to conventional compressors. The same compressor can operate in either cooling or heating (heat-pump) mode, ensuring the battery’s optimal working temperature. Typically, conventional compressors experience significant performance drops during very cold and very hot conditions, whereas centrifugal compressors exhibit much less variation across the working temperature range.

Could you elaborate on the utilization of "oil-less bearings" in the E-Cooling Compressor and the benefits they provide?

The Garrett refrigerant compressor utilizes oil-less bearings and operates at incredibly high speeds, contributing to more efficient energy management and supporting improved vehicle range. The absence of oil also allows for much more flexible positioning of the compressor within the system, providing greater packaging freedom for original equipment manufacturers (OEMs). Due to the oil-less bearing design, the rotor spins on a cushion of refrigerant gas, making it contact-less. As a result, this drastically reduces noise and vibration compared to conventional compressors.

Could you share some information about the customers you are collaborating with on the E-Cooling Compressor?

Garrett has received very positive responses from OEMs across the globe on the new cooling compressor. Currently we have signed proof-of-concept projects running with 10 customers within automotive and beyond in key regions.

Looking ahead, what further developments or innovations can we expect from Garrett Motion in the field of electric vehicle thermal management systems?

Garrett Motion is dedicated to delivering unique thermal management solutions for electric vehicles. Our innovative technologies, like the advanced high-power centrifugal refrigerant compressor, place us at the forefront of the EV industry. We’re committed to ongoing innovation to improve vehicle efficiency and promote environmental sustainability.