BorgWarner has secured a contract with a major Chinese vehicle manufacturer to supply its dual inverter with boost function, the Michigan, US-based global component supplier announced Feb. 8.

It said that its dual inverter with boost function will be used in a series of its customer’s plug-in hybrid (PHEV) and range-extended (REEV) electric vehicle passenger car platforms. BorgWarner, however, did not disclose the name of its Chinese customer who has placed this order.

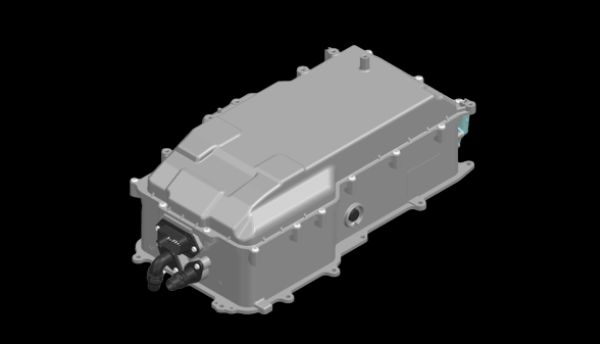

The boost module is directly integrated into the 400V dual inverter to achieve a higher power density, BorgWarner said, adding that the inverter also meets the local hybrid architecture standards within the Chinese market.

“This win expands BorgWarner’s product portfolio with this [original equipment manufacturer], marking the first 400V dual inverter with boost function,” the company said in a press note.

According to BorgWarner, its voltage-boosted dual inverter is specifically developed for hybrid vehicle models as an integrated solution. The product uses BorgWarner’s Viper platform to implement two inverters and a high-power boost module in a single, compact package, and achieves precise control of dual motors with a single, multicore control chip. Key benefits include increased power density and performance, cost reduction, and flexible integration that makes installation easy for automakers.

The dual inverter with boost will be manufactured and assembled in BorgWarner’s plant in Suzhou, China, with production expected to begin in September 2024.

Commenting on the new contract for the dual inverter, Stefan Demmerle, president and general manager of BorgWarner PowerDrive Systems, said, “As the hybrid vehicle market share continues to grow in China, supplying advanced technology like our boosted dual inverter to support and amplify OEM hybrid vehicle production is crucial. Our skilled engineering team, paired with our reputable quality standards and manufacturing processes, makes us a leader in this space and a great partner in the shift toward electrification.”